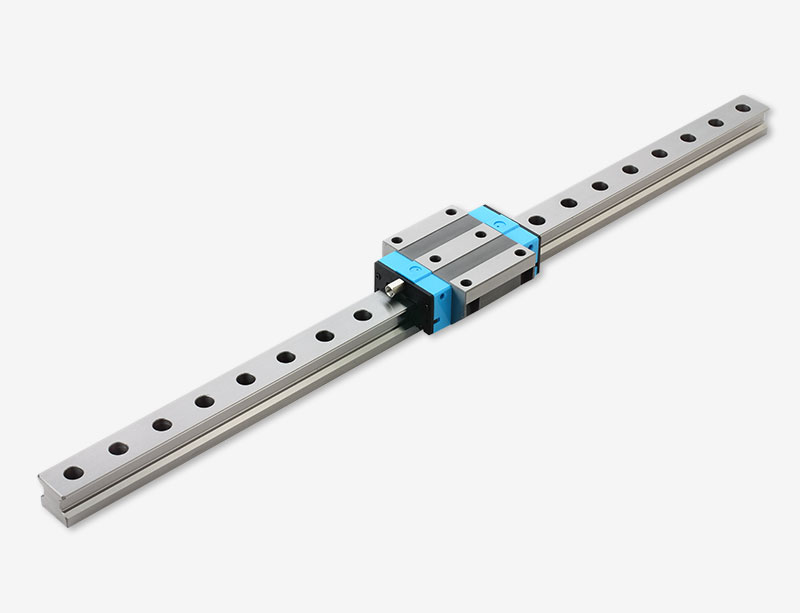

Precautions and troubleshooting of linear guide

Note for use:

Linear guide rail is a precision part, so it needs to be used with great care. Even if a high-performance linear guide rail is used improperly, it can not achieve the expected performance effect, and it is easy to damage the linear guide rail.

Therefore, the use of linear guide rail should pay attention to the following:

Rust prevention

When taking the linear guide rail directly by hand, the sweat on the hand shall be fully washed off, and the operation shall be carried out after the application of high-quality mineral oil. In rainy season and summer, special attention shall be paid to rust prevention.

Keep the environment clean

Keep the linear guide rail and its surrounding environment clean. Even if the small dust invisible to the naked eye enters the guide rail, it will increase the wear, vibration and noise of the guide rail.

Careful installation

When using and installing the linear guide rail, it is required to be careful. It is not allowed to punch strongly, hit the guide rail directly with a hammer, and transfer the pressure through the rolling body.

Installation tools should be suitable

Use proper and accurate installation tools for linear guide rail, try to use special tools, and try to avoid using cloth, short fiber and other things.

Troubleshooting:

The guide rail of industrial clamp is mostly made of steel or cast iron. In the long-term use process, there are different degrees of friction between the two contact surfaces, which will cause different degrees of scratches and strains on the surface of the guide rail, seriously affecting the processing accuracy and production efficiency of the equipment. Traditional repair methods usually adopt metal plate inlay or replacement, but it needs a lot of precise manufacturing and manual scraping. Repair requires many processes and a long time. Polymer composite material can be used to solve the problem of scratch and strain of machine tool guide rail. Because of its excellent adhesion, compressive strength, oil resistance and wear resistance, it can provide a long-term protective layer for components. It only takes a few hours to repair the scratched part of the guide rail and put it into use. Compared with the traditional method, the operation is simpler and the cost is lower.

Recently Viewed:

Products

News

- The reason and solution of noise in the running of linear guide rail 2019-11-11

- Introduction to linear guide 2019-05-22

- How to ensure the accuracy of linear guide 2019-05-22

- How to clean the linear guide? 2019-05-22

- Basic knowledge of linear guide 2019-05-22

- How to select the linear guide correctly 2019-05-22

- Installation procedure of linear guide rail 2019-05-22

- Choosing the right linear guide needs to look at these! 2019-12-31

- Four points for attention in installation of linear guide rail 2019-11-11