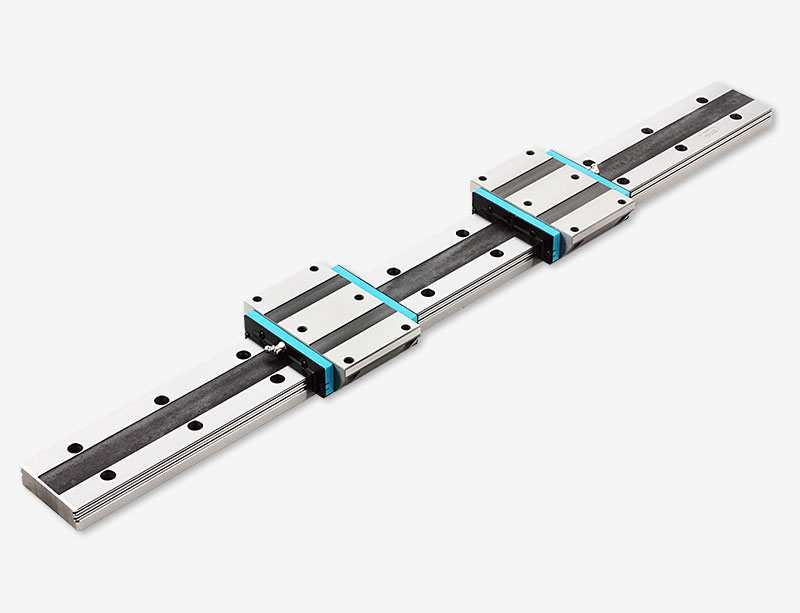

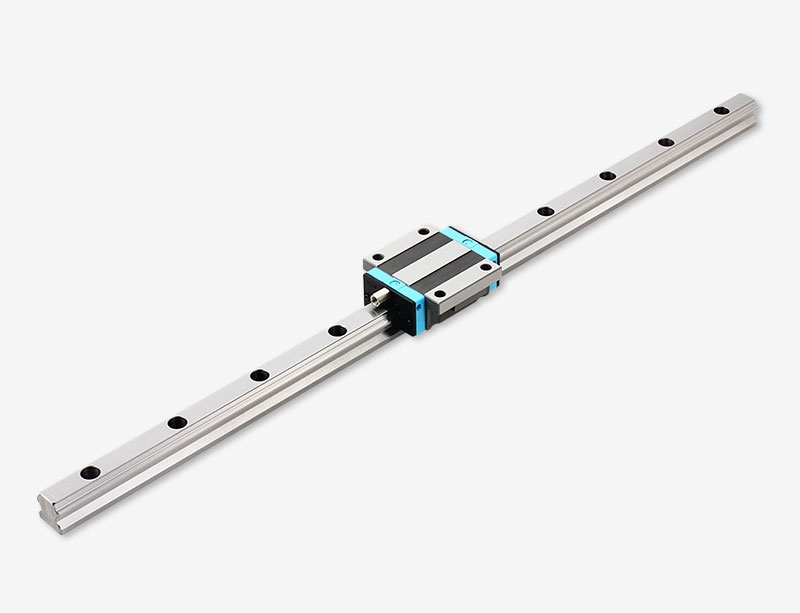

Characteristics of rolling linear guide pair

Compared with the sliding guide used in CNC machine tools, the rolling linear guide pair has excellent characteristics and excellent performance.

1. Friction characteristics

The rolling linear guideway pair has outstanding advantages in friction characteristics. Its friction resistance is much smaller than that of the sliding guideway. The general friction coefficient μ = 0.002 ~ 0.004, which is about 1 / 50 of the sliding guideway. The starting friction and dynamic friction are nearly equal. When the speed changes, the μ value is stable, the movement is light, flexible and stable, so the high-speed movement can be realized and the production efficiency is improved.

2. Kinematic characteristics

Because the friction of the linear rolling guide pair is very small, there is no vibration when starting, and there is no crawling phenomenon when moving at low speed. When the preload is applied, the clearance can be eliminated and the rigidity can be improved. In addition, it has the function of automatic center adjustment and compensation of installation base surface error, so its overall motion accuracy is high, so it is suitable for high-precision and high-performance mechanical products. In addition, because the rolling linear guide pair has a good error equalization function, it is also called "magic guide" and "artifact guide". The movement of rolling linear guide rail is realized by steel ball or roller rolling. The friction resistance of guide rail pair is small, the difference between dynamic and static friction is very small, and the following performance is excellent. It is not easy to creep at low speed, that is, the time interval between driving signal and mechanical action lag is very short, which is beneficial to improve the response speed and sensitivity of CNC system, and to achieve high positioning accuracy. As a rolling functional part with high positioning accuracy, the rolling linear guide pair is suitable for frequent starting or reversing of moving parts. It can set the positioning accuracy of the machine tool to the ultra micron level. At the same time, the preload of the guide pair can be increased appropriately according to the needs to ensure that the steel ball or roller does not slide, realize the smooth movement, and reduce the impact and vibration of the movement. The rolling linear guide pair is also suitable for high-speed linear motion, and its instantaneous speed is about 10 times higher than that of the sliding guide.

3. Life characteristics

In the sliding guide, most of the energy is consumed in the form of wear energy, so the wear is fast and it is difficult to maintain high precision for a long time. On the contrary, the rolling guide pair has small friction and less wear, which can keep high precision for a long time. In addition, because multiple rolling elements are used as the support in the rolling guide pair, and the raceway can easily obtain high machining accuracy and high surface hardness, the rolling linear guide pair has a long working life. Due to the floating of oil film, the motion accuracy error of sliding guide surface can not be avoided. In most cases, fluid lubrication is limited to the boundary area, and the direct friction caused by metal contact is inevitable. In this kind of friction, a lot of energy is wasted by friction loss. On the contrary, due to the less friction energy consumption, the friction loss of the rolling surface is also reduced, so the rolling linear guide system can keep high precision for a long time. At the same time, because the use of lubricating oil is also very small, which makes it very easy to design and maintain the lubrication system of the machine tool.

4. Bearing characteristics

The rolling linear guideway pair has good bearing capacity, and can bear the force and moment load in different directions, such as up and down, left and right, as well as pitch moment, yaw moment and rotation moment, so it has good load adaptability. In the process of design and manufacture, the appropriate preload can increase the damping, improve the vibration resistance and eliminate the high frequency vibration. However, the lateral load that the slide guide can bear in the direction of parallel contact surface is small, which is easy to cause the poor running accuracy of the machine tool.

5. Driving characteristics

The driving power is greatly reduced, which is only 1 / 10 of that of ordinary machines. Because of the small friction resistance, the machine tool with rolling linear guide can make the power source and power transmission mechanism needed miniaturized, so that the driving torque is greatly reduced, the power required by the machine tool is reduced by 80%, and the energy-saving effect is obvious. It can realize the high-speed movement of the machine tool, and the efficiency of the machine tool can be increased by 20% - 30%.

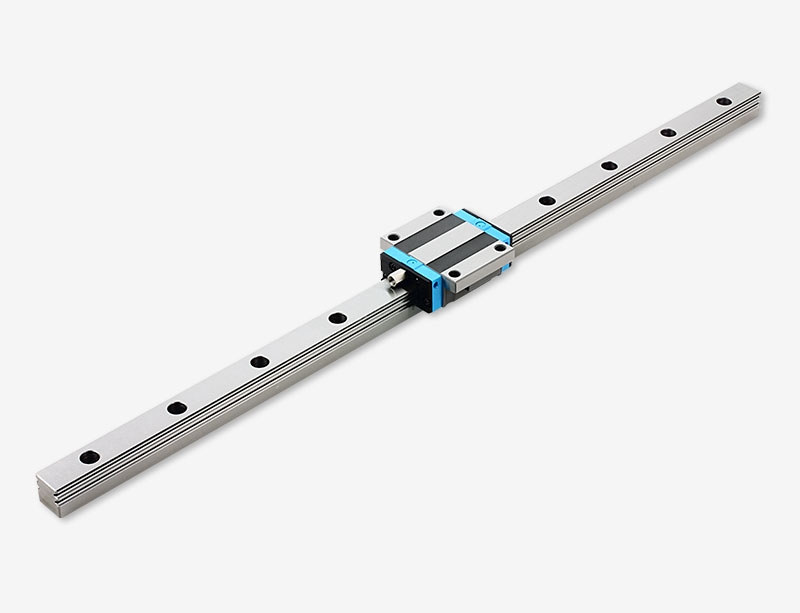

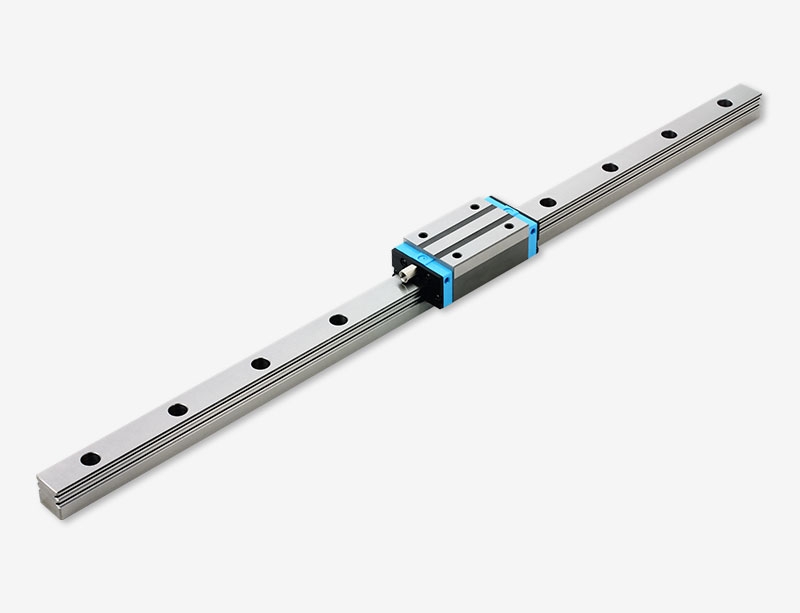

6. Interchangeability

It simplifies the design and manufacture of mechanical structure. When the guide pairs are used in pairs, it has the "error homogenization effect", so as to reduce the machining accuracy requirements of the basic parts (guide installation surface), reduce the mechanical manufacturing cost and machining difficulty of the basic parts. The traditional sliding guide rail must be scraped and grinded, which is both time-consuming and time-consuming. Once the accuracy of the machine tool is poor, it must be scraped and grinded again. The rolling guide rail has interchangeability. As long as the slider or guide rail or the whole rolling guide rail pair is replaced, the machine tool can get high precision again.

7、 Economic characteristics

Because of its small friction resistance, less wear, convenient lubrication, maintenance and repair, the maintenance cost of the rolling linear guide pair is low. In addition, the rolling linear guide pair also has a good interchangeability, which is easy to form standardization and serialization, and is produced by professional manufacturers in batches, making it very convenient for users to select, thus reducing the design time. In addition, energy saving and fuel saving is another remarkable feature of linear rolling guide pair. THK company of Japan has tested the performance of single axis surface grinder using sliding guide and three axis surface grinder using rolling guide. The result shows that the power consumption of using sliding guide is 16.7 times of that of rolling guide pair. In view of the outstanding advantages of the rolling linear guide pair, it is widely used in the mechanical industry, including various CNC machine tools, precision worktables, industrial robots, medical devices, testing instruments, light industrial machinery and moving machinery.