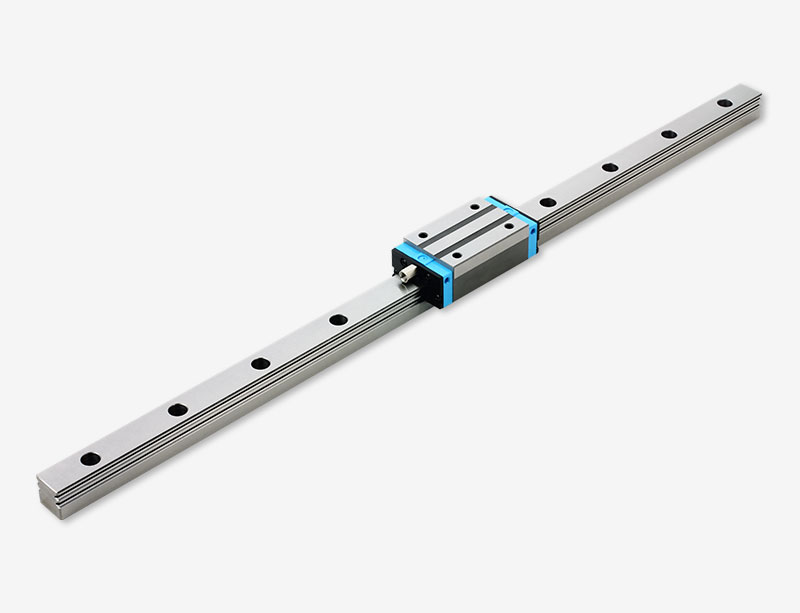

Basic knowledge of linear guide

Linear guide rail is used to support and guide moving parts to do linear reciprocating motion. It can achieve high-precision linear motion under high load, and has higher rated load than linear bearing. The characteristic is that it can move freely without gap, and can bear certain moment at the same time. It is suitable for various working environments and can maintain high precision for a long time.

Material of linear guide rail:

The material of sliding block is generally divided into carbon steel and stainless steel (the linear guide rail of stainless steel material shall be selected in places requiring corrosion resistance).

The common surface treatment of carbon steel linear guide rail is as follows:

1. Compared with stainless steel, low-temperature black chromium plating (black surface, similar to blackening) has lower cost and higher corrosion resistance;

2. Chrome plating, the surface coating film has high hardness and excellent wear resistance.

Accuracy class of linear guide rail:

The precision grade of linear guide rail is divided into ordinary grade (c), advanced grade (H), precision grade (P), super-0 precision grade (SP) and super super precision grade (up). Different accuracy levels directly lead to linear guide rail, and common level and advanced level can be selected for different general application occasions of combination height h, width n and travel parallelism error to meet the demand.

Clearance and preloading of linear guide rail:

The gap and preload of linear guide directly affect the rigidity of linear guide.

Clearance: clearance between slide, rail and steel ball.

Preloading: preloading the ball with a negative load (increase the diameter of the ball) using the negative gap between the ball and the rail. Improve rigidity and eliminate clearance. The preloading level is divided into light preloading (Z0), medium preloading (ZA) and heavy preloading (ZB).

The application is as follows:

Light preloading (Z0): minimal vibration, good load balance, light and precise movement

Medium preloading (ZA): moderate vibration, moderate external suspension load

Heavy preloading (ZB): with vibration and impact, bearing external suspended load

Recently Viewed:

Products

News

- Precautions and troubleshooting of linear guide 2019-05-22

- Introduction to linear guide 2019-05-22

- Choosing the right linear guide needs to look at these! 2019-12-31

- Installation procedure of linear guide rail 2019-05-22

- Four points for attention in installation of linear guide rail 2019-11-11

- The reason and solution of noise in the running of linear guide rail 2019-11-11

- How to clean the linear guide? 2019-05-22

- How to ensure the accuracy of linear guide 2019-05-22

- How to select the linear guide correctly 2019-05-22