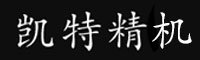

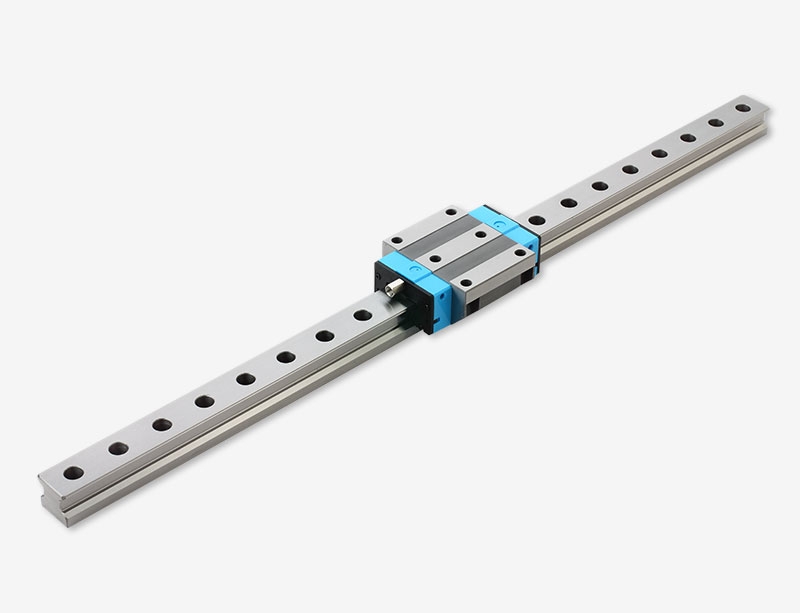

LGR-LL roller super high seal dust guide

Description:LGR series roller guide pair uses cylindrical roller instead of steel ball. The roller is in...- Cname:Linear Guide Rail

- productnum:LGR-LL

- Views:0

- Date:2020-01-14 10:23:19

- Contact

1. Large bearing capacity and high rigidity

LGR series roller guide pair uses cylindrical roller instead of steel ball. The roller is in line contact with guide rail and sliding block. When bearing high load, it only forms small elastic deformation, which greatly improves the rigidity of guide pair. The guide pair adopts db45 degree combination, which can bear up, down, left, right and equal loads.

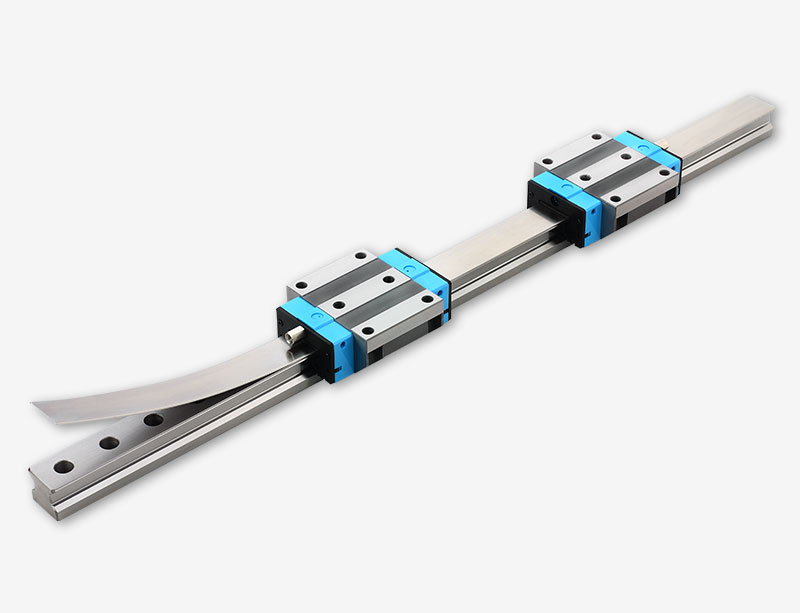

2. Strong sealing and dustproof ability

Both ends of the slide block are equipped with sealed end covers, and the inside and bottom of the slide block are equipped with sealed negatives, which has excellent dust-proof performance. At the same time, the installation hole of the guide rail of the clamp is equipped with a screw hole cap to prevent dust from accumulating, thus ensuring the service life of the product. Users with higher sealing requirements can choose stainless steel protective belt plate and install double-layer sealing end cover.

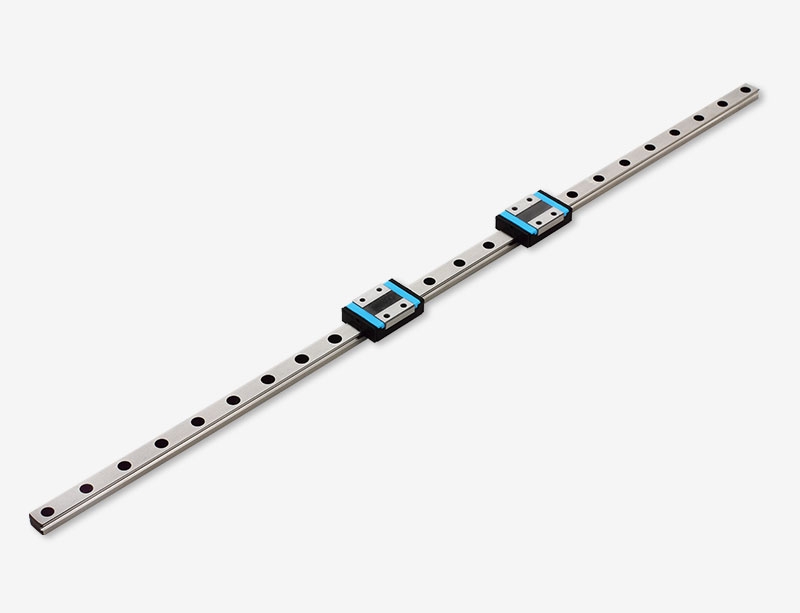

3. High speed, high acceleration and deceleration

The main accessories of LGR series roller guide pair are made of impact resistant materials, which can realize high-speed movement with the maximum speed of 120m / min and the maximum acceleration of 2G.

The guide rail is made of high-quality alloy steel. The positioning side and raceway are grinded at the same time to ensure the raceway's precise geometry. The cage can prevent the rollers from scattering. The return device is made of high-strength engineering materials and guides the roller to reverse to form a continuous circular motion. Sealing the end cover and sealing the negative film is a necessary part for dust prevention. The lubrication of the guide pair is carried out by injecting lubricant into the oil filling cup.