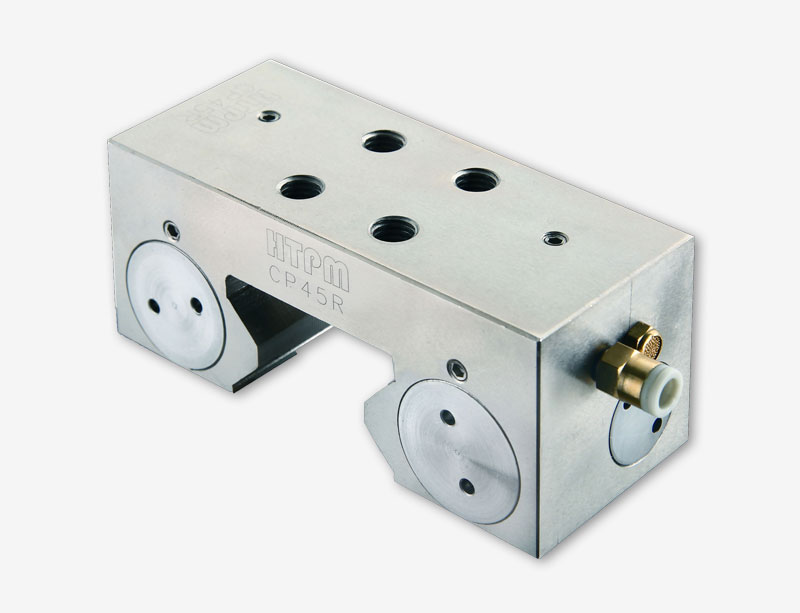

The introduction of rail clamp

Guide rail clamp, also known as guide rail brake / guide rail lock /, is a brake element directly clamping linear guide rail (LM guide rail, etc.) or optical axis. Air pressure, hydraulic pressure, manual and electric control modes are optional.

Guide rail clamp refers to the product that directly clamps the guide rail and linear axis of the linear guide rail to brake or maintain the position of the sliding table. It solves the problem of insufficient rigidity when using general driving parts such as motor + ball screw and cylinder to maintain the position, and improves the performance of the device.

Its purpose is as follows:

Keep the position at any position; keep the angle at any rotation angle; improve the safety (keep the position when the power is turned off and prevent falling); improve the rigidity of the device; prevent deformation, shaking and vibration; keep the position automatically.

Its characteristics are as follows:

To prevent deformation, shaking and vibration of the device, which has no effect on the rigidity of driving parts such as motor, ball screw, air cylinder, etc., can obtain a higher position to maintain the rigidity and inhibit the deformation, shaking and vibration of the device.

Reduce the load of the driving type and prevent the load to the feed direction from being transferred to the driving type parts when the slide stops.

High retention force, through the unique internal structure, the guide rail lubricated by grease can also obtain great retention force.

It is small and easy to install, and can be installed between two sliding seats which are usually free space.

It has no effect on the linear guide rail, and the clamping position avoids the rolling surface of the ball and roller.