What are the factors that affect the running speed of linear module

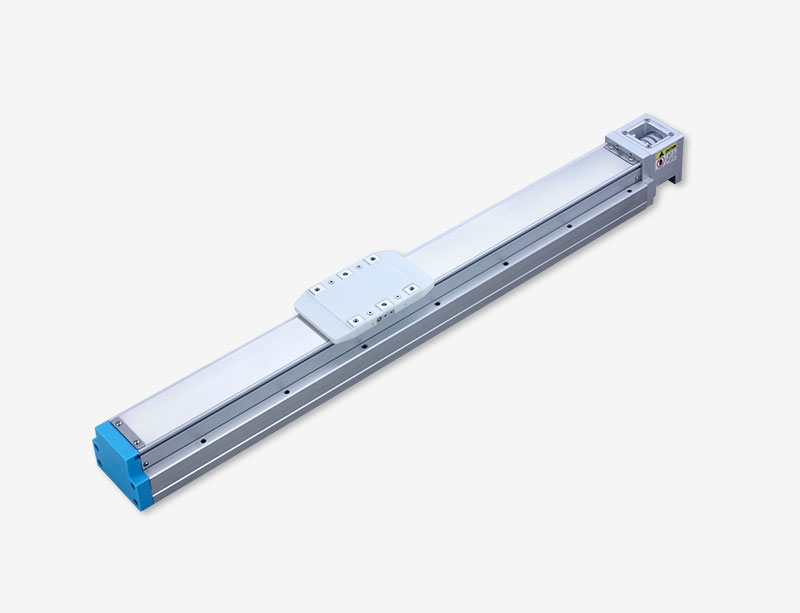

Linear module is a kind of universal transmission component in automation equipment, and its application field is more and more extensive. Different industries consider the effective travel, load-bearing, repeated operation accuracy, operation speed and use environment of linear module to find satisfactory linear module. The running speed is one of the most concerned parameters for linear module.

Different enterprises have different operation speeds for linear modules. Some enterprises need the operation speed of linear modules to reach 200 mm / s, while some enterprises need a higher operation speed of 2000 mm / s to ensure the normal operation of machinery, so as to improve the production efficiency of enterprises and increase the economic benefits of enterprises. So what are the factors that affect the running speed of linear module?

Motor driving device is an important factor of linear module running speed. Linear module running needs the cooperation of motor driving device. Different types of motor devices have different running speed. The common motors on the market are servo motor and stepping motor.

Internal structure:

The internal structure of linear module can be divided into synchronous belt type and screw type. The linear module of synchronous belt runs faster than the linear module of screw rod type. Although the running speed of screw linear module is not as fast as that of synchronous belt type, the force and accuracy are better than that of synchronous belt type linear module. Generally speaking, if the force is large, the stroke is short, and the accuracy requirements are relatively high, the screw rod linear module can be selected; if the force is general, the stroke is long, and the accuracy requirements are not high, the synchronous belt linear module can be selected.

Maintenance:

We all know that the better the maintenance of anything, the longer it takes, and the better the effect. Especially for the linear module, if the maintenance is not carried out after normal operation, it is easy to produce wear in the operation, resulting in poor speed and accuracy. Therefore, maintenance is very necessary and important.